Kim Youngbum, President, Kolon Industries

According to the industry on the 30th, Kolon Industries will complete the expansion of the aramid pulp production line at its Gumi plant within the year. Through this, its annual production capacity of pulp will increase from 1,500 tons to 3,000 tons. At the end of December last year, the company also 'doubled up' its aramid production capacity from 7,500 tons to 15,000 tons per year. This means that the large-scale aramid investment project, which started in 2021 to grow new growth engines, will be completed.

However, the aramid effect is expected to begin in earnest after the fourth quarter. This is because there is no problem with the operation of the new plant in the third quarter, but regular maintenance of existing production facilities is underway.

Brake pads made of aramid pulp from Kolon Industries / Photo courtesy of Kolon Industries

Aramid is a new material that is five times stronger than steel and can withstand high temperatures of 500 degrees Celsius. It is attracting attention as an alternative material in high-tech industries such as electric vehicles, optical cables, and aerospace. Aramid pulp is a product made by cutting aramid yarns into shavings, which are used to reinforce automobile parts.

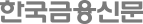

Kolon Industries focuses on tire cord, petroleum resin, and fashion. Last year, sales and operating profit fell 6 percent and 35 percent, respectively, from the previous year due to the sluggish industry. Its operating profit in the first half of this year was only KRW 90 billion, down 20 percent from last year. Aramid's contribution to the company's earnings is urgently needed to turn things around.

Source: Financial Supervisory Service Electronic Disclosure System

The restructuring of underperforming businesses is also expected. The company began a full-scale restructuring of its unprofitable PET film business earlier this month. Kolon Industries plans to organize its business by establishing a joint venture with SK Microworks, which was acquired from SKC by private equity fund Hahn & Company. Kolon Industries will hold an 18 percent stake in the joint venture in exchange for an in-kind contribution of its Gimcheon PET film plant.

The film and electronic materials division, which includes Kolon Industries' film division, has posted an operating loss of KRW 15 billion in the first half of this year, following losses of about KRW 157 billion in 2022 and 2023. As Kolon Industries has a small stake in the joint venture, its results will not be reflected in the future.

Gwak Horyung (horr@fntimes.com)

![코스피 6300인데···KB금융, 12거래일 연속 외인 '순매도' 이유는 [금융지주 밸류업 점검]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=69&h=45&m=5&simg=2026022621383900871b4a7c6999c121131189150.jpg&nmt=18)

![[속보] KAI 노조 "오늘 사장추천위 열린다"...사측 "확인 못해"](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=69&h=45&m=5&simg=20260227135534054450d260cda7511817679169.jpg&nmt=18)

![[DQN] KB, 시장가치 ‘독주’…우리 '고전' 신한 ‘하락 반복'](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=69&h=45&m=5&simg=2026022715234305700c1c16452b012411124362.jpg&nmt=18)

![‘은평뉴타운폭포동힐스테이트4-2단지’ 38평, 2.7억 내린 10.5억원에 거래 [하락 아파트]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=69&h=45&m=5&simg=2024022010523800318b372994c95125129250237.jpg&nmt=18)

![서초구 '신반포' 35평, 17.3억 오른 50억원에 거래 [일일 신고가]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=69&h=45&m=5&simg=2025061908193804321e41d7fc6c2183101242202.jpg&nmt=18)

![[그래픽 뉴스] “돈로주의 & 먼로주의: 미국 외교정책이 경제·안보에 미치는 영향”](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=298&h=298&m=1&simg=202602261105472649de68fcbb3512411124362_0.jpg&nmt=18)

![[그래픽 뉴스] 워킹맘이 바꾼 금융생활](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=298&h=298&m=1&simg=202602021638156443de68fcbb3512411124362_0.jpg&nmt=18)

![[그래픽 뉴스] 매파·비둘기부터 올빼미·오리까지, 통화정책 성향 읽는 법](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=298&h=298&m=1&simg=2026022714105702425de68fcbb3512411124362.jpg&nmt=18)

![[그래픽 뉴스] 하이퍼 인플레이션, 왜 월급이 종잇조각이 될까?](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=298&h=298&m=1&simg=202601141153149784de68fcbb3512411124362_0.jpg&nmt=18)

![[그래픽 뉴스] 주식·채권·코인까지 다 오른다, 에브리싱 랠리란 무엇일까?](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=298&h=298&m=1&simg=2026022714100604994de68fcbb3512411124362.jpg&nmt=18)

![[신간] 고수의 M&A 바이블](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=81&h=123&m=5&simg=2025091008414900330f8caa4a5ce12411124362.jpg&nmt=18)

![[신간] 리빌딩 코리아 - 피크 코리아 극복을 위한 생산성 주도 성장 전략](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=81&h=123&m=5&simg=2025032814555807705f8caa4a5ce12411124362.jpg&nmt=18)

![[서평] 추세 매매의 대가들...추세추종 투자전략의 대가 14인 인터뷰](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=81&h=123&m=5&simg=2023102410444004986c1c16452b0175114235199.jpg&nmt=18)

![[신간] 이게 화낼 일인가?](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=81&h=123&m=5&simg=2026010610254801367f8caa4a5ce12411124362.jpg&nmt=18)

![[AD] 현대차, 글로벌 안전평가 최고등급 달성 기념 EV 특별 프로모션](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=89&h=45&m=1&simg=20260106160647050337492587736121125197123.jpg&nmt=18)

![[AD] 현대차 ‘모베드’, CES 2026 로보틱스 부문 최고혁신상 수상](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=89&h=45&m=1&simg=20260105103413003717492587736121125197123.jpg&nmt=18)

![[AD] 기아 ‘PV5’, 최대 적재중량 1회 충전 693km 주행 기네스 신기록](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=89&h=45&m=1&simg=20251105115215067287492587736121125197123.jpg&nmt=18)

![[카드뉴스] KT&G, 제조 부문 명장 선발, 기술 리더 중심 본원적 경쟁력 강화](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=89&h=45&m=1&simg=202509241142445913de68fcbb3512411124362_0.png&nmt=18)

![[AD]‘황금연휴에 즐기세요’ 기아, ‘미리 추석 페스타’ 이벤트 실시](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=89&h=45&m=1&simg=20250903093618029117492587736121166140186.jpg&nmt=18)